...

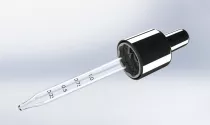

Next-level technology

We push boundaries

A key factor in the further development of our enterprise is the expansion, diversification, and refinement of our process chain. At the heart of this is our technological expertise. In addition, we are also constantly optimising our performance in the associated process segments of sales, administration, and customer services.

Our process chain

from product development to delivery

Sales & service

Zuverlässig und kompetent

Development

Collective expertise

Design

Speed – our guiding principle

Mould construction

Precision moulds:

for top quality

Machine construction

In-house developments for optimum manufacturing quality

Production

Sophisticated hygiene and technology in the material flow

Assembly

Highly dynamic process

and assembly technology

Quality control

Clean manufacturing –

inspected and documented

Storage & shipping

High capacities –

short delivery times

At our premises in ansbach, we offer you:

Everything from a single source

From development and design to our own mould and machine construction as well as production, warehousing and shipping. Coupled with our many years of experience in the pharmaceutical, medical, food supplement, lifestyle and foodstuffs industries, we are able to offer you an all-round and all-inclusive package when choosing your packaging supplier.

1

Sales & Service

Reliable and competent

Comprehensive service and expert advice have always been a priority at Heinlein. We offer professional support with finding suitable packaging, as well as in the areas of processing, sealing and conveyor technology. As our customer, you benefit from our long-standin g experience, true to our motto:

Heinlein helps solve problems.

As an additional service, we can assist with the professional identification of items and administration methods that best suit your requirements. Suitable dosing tests are performed directly on your product, based on prescribed dosing regulations. We use the findings to determine the best product combination for your needs. This saves time and creates transparent values thanks to documented procedures.

Good service does not end with the delivery of our products. We would also be glad to assist you with system configuration and help with any related questions or problems: by phone or on site.

Under "Sales & service", select the sales employee who is assigned to you.

Martin Gruner and his team look forward to hearing from you!

- Personal point of contact

- Assistance with finding suitable packaging

- Professional identification of suitable items and administration methods

- Assistance with configuring your system, whether by phone or on site

2

Development

Collective expertise

Our technology centre in Ansbach models the entire development process of the products: from the initial idea to the development and design, and ultimately to series production. Here, engineers, technicians, and experts from different departments come together and work hand in hand. In this manner, products are created which reflect the entirety of our collective know-how: high-quality workmanship combined with functional reliability and, above all, production that is aligned towards economies of scale through maximum-efficiency high-volume production.

Our experienced team of developers is as focused on expanding our existing range as it is on creating customised packaging for our customers. The equipment we use for our research and development work comprises the latest technology (3D printers, latest CAD programs), testing equipment, workshops for test runs, a design department, and our mould construction department for building prototypes and moulds. Cooperation partners such as the engineering faculty of the Ansbach University of Applied Sciences (specialists in plastics technology) also assist us with specific requirements, e.g. through the use of magnetic resonance tomography.

- Customer-specific developments

- Short communication paths, standardised development processes

- Development of medical products and pharmaceutical primary packaging in compliance with MD 93/42/EEC,

- ISO 13485 and FDA

- Full simulations, 3D models, initial functional models

- Usability evaluation

3

Design

Speed – our guiding principle

The core competencies of mould construction are brought together in the company’s own engineering design department. Here, the necessary series production moulds are designed, engineered and manufactured, and a pool of over a hundred ready-to-use injection moulds is managed. In addition to wide interfaces and short communication paths between the departments, the in-house design workflow greatly accelerates the process. New moulds can be built faster, and problems with moulds identified and rectified more quickly.

- Construction of pilot moulds

- Fast reaction times from customer support

- More than 100 ready-to-use proprietary injection moulds

4

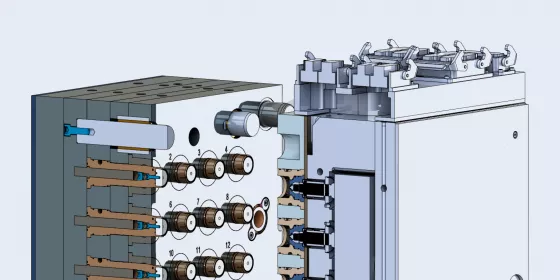

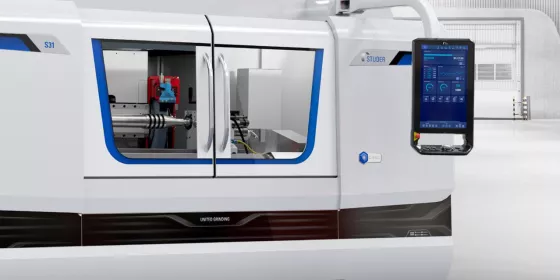

Mould construction

Precision moulds:

for top quality

Mould construction is a traditional affair at Heinlein By 1932, we were already manufacturing sophisticated, high-quality moulds. Our current injection moulds are designed to satisfy the complex requirements of the pharmaceutical industry. Crucial factors in this respect are precision and dimensional accuracy, high output quantities, and short cycle times. Our mould construction represents the combination of maximum process accuracy and uncompromising service. High productivity and system efficiency ensure that we reliably achieve our target output. The manufacturing and adaptation of our moulds, as well as the provision of interchangeable mould inserts for short maintenance and retooling times, ensure rapid, smooth production.

- In-house manufacturing of injection moulds

- Manufacturing of precision moulds based on customer-specific adaptations or new designs

- Outfitting with CNC, milling, vertical eroding, turning, and grinding machines as well as the relevant peripherals

- Adaptation of format parts and conveying technologies, e.g. vibratory bowls, feed rails, and sorters

- Manufacturing of screwing units and screw heads

- Quick implementation of maintenance and repair services (in-house)

- High degree of reliability for deliveries

> 95% of all deliveries

5

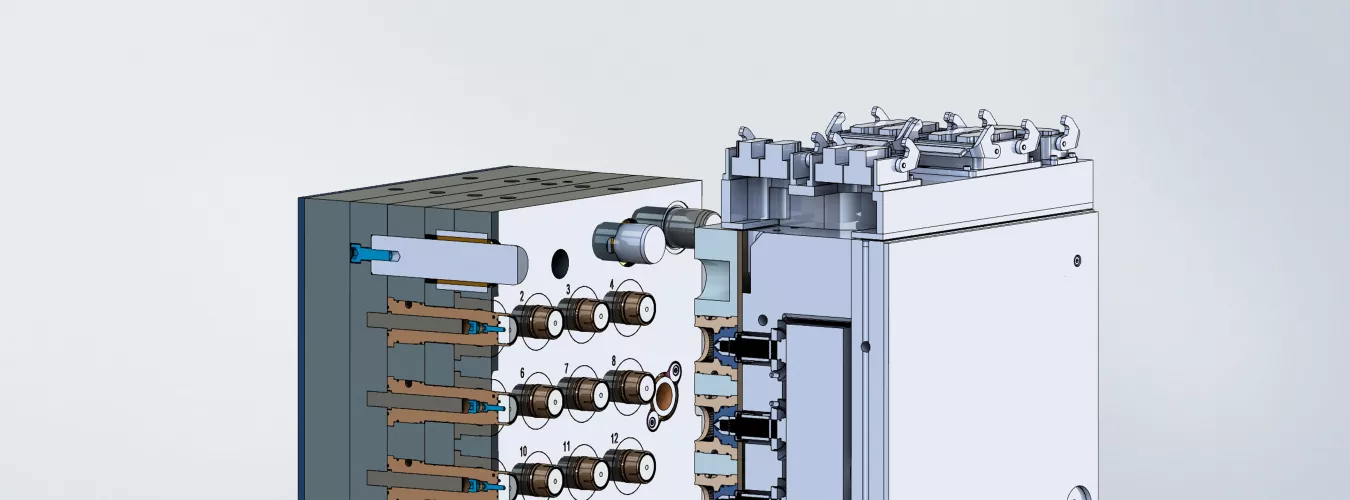

Machine construction

In-house developments for

optimum manufacturing quality

Our in-house developments are executed to the same high standards as customer orders. This pooling of expertise within our own company enables a great degree of individuality and innovation. From design and programming to the use of camera technology, we create our assembly machines entirely with our own resources. Comprehensive support is assured throughout the production process – an additional advantage that will benefit you as our customer!

- In-house design, construction and programming of all assembly machines

- Quick and flexible system adaptation to new closure types and combinations

- In-house maintenance and servicing

- Construction of customer-specific accessories for filling lines

- High degree of reliability for deliveries

> 95% of all deliveries

6

Production

Sophisticated hygiene and technology

in the material flow

Innovative injection moulding technologies and in-line manufacture form the basis for the production of sophisticated primary packaging. With intelligently coordinated process workflows, our production is fully geared towards high speeds and compliance with the highest hygiene standards. We process the relevant pharmaceutical grade material with the necessary permits. We also handle plastic as a raw material with the relevant degree of care: one example is our participation in the "Zero granule loss" initiative.

Cutting-edge manufacturing and assembly systems are in operation for our international customers around the clock. We have equipped our injection moulding machines with state-of-the-art camera systems, which inspect every individual closure. Our machine pool comprises 41 injection moulding machines from renowned manufacturers such as Arburg, Krauss-Maffei and Netstal, some of which have already been fitted with hybrid drives, or are fully electric machines. Manufacturing takes place under conditions with low microbiological contamination, or also in a clean room where required. The high purity of the material, in combination with a hygienically and technically flawless material flow, is guaranteed by a system which distributes the plastic granules via closed stainless steel pipes from the silos to the individual machines. Furthermore, Class 9 dust filter installations ensure the constant cleanliness of the pipe systems.

- In-line production: fully automatic material feed and closure transport

- Injection, assembly, and packaging procedures in a single work step

- Camera checks

- Pest monitoring and HACCP

- State-of-the-art machine pool

- 3-shift operation, 24/7

- Regular training on HACCP and GMP topics

- High degree of reliability for deliveries

> 95% of all deliveries

7

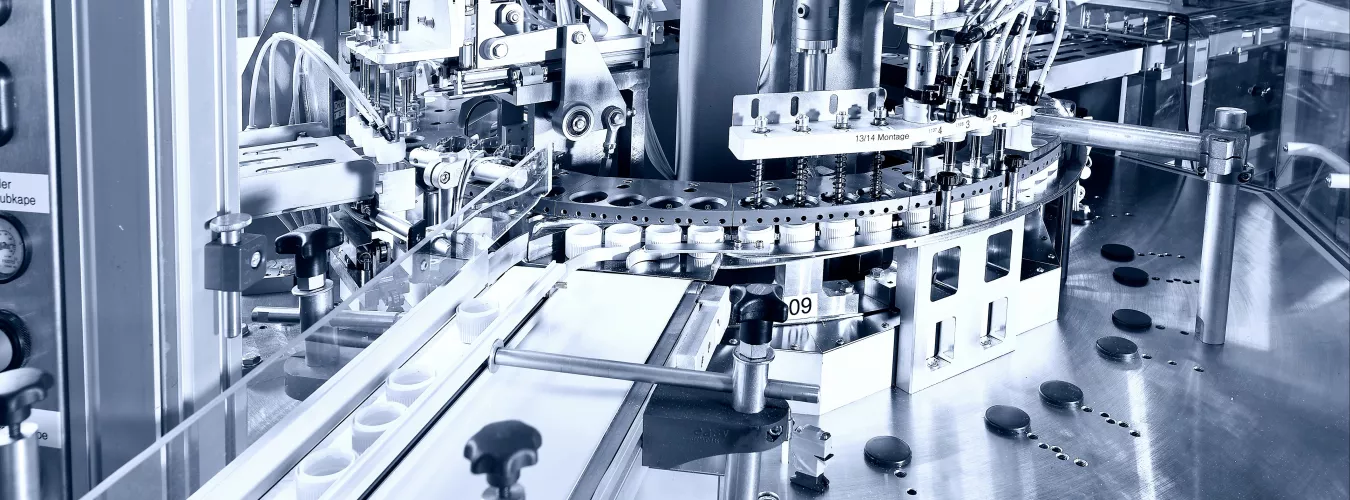

Assembly

Highly dynamic process

and assembly technology

Over 19 high-performance assembly machines ensure the highest manufacturing quality. With our in-line manufacturing process, the relevant parts are automatically forwarded from the injection moulding machine to the assembly machine. The assembly machines are designed and built in-house from standard components, which means that we are able to rapidly react to customer-specific requirements. Whether it is a question of single components or entire product groups: our precisely coordinated technologies ensure a completely pre-assembled product upon delivery. Up to four parts can be assembled in a single work step. Before it is transferred to the transport packaging, each individual part is inspected with a high-precision online camera system. In this manner, we guarantee a high degree of quality and reliability, thereby creating the basis for process reliability during your further processing.

- Assembly machines developed in-house

- Up to four parts assembled in a single work step

- Quality control via camera systems

- Optical measuring machine for CNC

- High process reliability during further processing

8

Quality control

Clean manufacturing –

inspected and documented

With cutting-edge CAQ systems and measuring equipment, we promote continuously documented process quality. Visual and measurement inspections are conducted regularly.

Heinlein works according to a standardised quality management system which is certified in accordance with ISO 9001, ISO 13485 and ISO 15378. This QM system also includes sub-systems for corrective and preventative error handling (CAPA). Thanks to a binding change control procedure, we also ensure that the validated state of a process is not negatively influenced by changes.

- Latest CAQ systems and cutting-edge measuring equipment for documented process quality

- Regular visual and measurement inspections

- Optical 3D CNC measuring machines from Werth, Zeiss, Mitutoyo

- 100 percent checks via the use of camera systems

- High product reliability

9

Storage & shipping

High capacities –

short delivery times

A modern high-bay warehouse with 3,600 spaces for pallets and climate-controlled storage rooms ensures high turnaround and short delivery times. Thanks to our wide range of products, we are able to react promptly to customer inquiries and deliver the desired items on a just-in-time basis. With our three loading ramps, we are currently able to process multiple deliveries simultaneously and load lorries without long waiting times.

- High level of hygiene and controlled warehousing conditions

- Climate-controlled storage areas

- Safety stock/delivery capacity

- Quick loading for forwarders