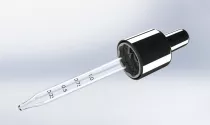

Uncompromising quality

We create new standards

High functionality, reliability and product safety are our yardsticks:

QUALITY is our highest priority at all times, to ensure your satisfaction and the safety of patients, consumers and third parties when using our products.

We guarantee the highest standards of quality by employing cutting-edge measuring equipment in our specialized measurement department, as well as technical and optical testing facilities. Planned results are verified during implementation with the use of the latest measurement and testing equipment and methods, under the supervision of our qualified employees. Furthermore, automated and optical testing systems can be integrated to operate in parallel to the process.

This means that electronic inspections are carried out on virtually every product based on a large number of characteristics. The consistent and reproducible documentation of workflows, inspections, and event data is ensured through the use of modern IT systems. By doing so, we ensure the fulfilment of the highest standards.

For you, this means maximum safety, high-quality products, less downtime, and lower costs.

Seal of quality

A certified partner by your side

All production-relevant processes at Heinlein Plastik-Technik are documented in detail. This ensures the consistent batch tracking of all manufactured components throughout the entire value chain. All components, as well as the end product, are meticulously inspected at various points in time during the production process. They comply with the stringent requirements for pharmaceutical primary packaging. Manufacturing, assembly, and packaging take place under the highest hygienic conditions. The Heinlein management system is certified according to the international standards ISO 9001, ISO 13485 and ISO 15378. Our predominantly international customers can always be assured of the procedurally and hygienically sophisticated manufacture, assembly, and packaging of the primary packaging materials, which takes place under controlled conditions.

Our certificates

Product certificates

Company certificates

We would be delighted to place our strong entrepreneurial spirit, knowledge and technological competency at your disposal as well!

Do you have questions or require specific information? Please do not hesitate to contact us.

sales@heinlein-plastik.de

Customer satisfaction

Your ideas help us constantly improve the overall performance of the company.

Hence, your opinion of our products and services is extremely important. Each year, numerous customers evaluate our range of products and services. This enables us to proactively fulfil the requirement of a continuous improvement process and optimise our services through reported personal experiences and suggestions. We are thankful for any feedback we receive.

The participants in our survey say:

"We can definitely recommend Heinlein Plastik-Technik!"

To customer satisfaction survey

We request customers and business partners who have established their own supplier evaluation system to send us this assessment by the end of the first quarter of the subsequent year at: info@heinlein-plastik.de. If you would like to tell us something independently of the customer satisfaction survey, please get in touch with your personal point of contact under "Sales & service".

Quality support

Do you have any questions?